P5 Sublifix Ink

This sublimation ink set has been optimized for the revolutionary direct-printing, inline-fixation concept of the Durst P5 iSub printer. The result is an unrivaled package for direct polyester printing, allowing a massive reduction of paper waste and energy consumption, combined with the potential to linearly scale production increase. In addition, extensive research has been carried out in order to have access to an impressive variety of transfer papers, including light and low coated papers.

Available Colors

Printer Platform

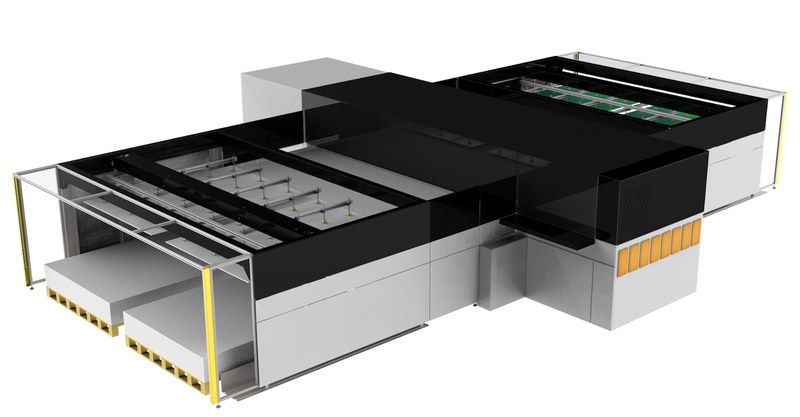

- P5 TEX iSub

Benefits

- Fast drying

- Excellent vibrancy and color gamut

- Optimized for inline fixation

- Astonishing sharpness for direct printing

- Reduced water consumption - no wash requirements for soft signage

Substrate Application Example

- Direct and transfer printing onto synthetic polyester fabrics

- Blended fibres(min 80 % PES)

- Transfer printing onto pre-treated rigid substrates

Compliance

ECO PASSPORT by OEKO TEX

Substrate List

Please get in touch with your local distributor to learn about tested substrates and suggested print settings.

Disclaimer: Any written information, spoken technical advice and correspondence represents the currently available product information to Durst, this also applies to information supplied from tests and samples. All technical information and advices do not constitute a guarantee or warranty for specific product properties or its suitability for specific applications. The testing and guarantee to achieve a certain product performance are the responsibilities of the manufacturer of these products, Durst accepts no liability and provides no guarantee in this respect.

We therefore recommend that every print manufacturer thoroughly tests the production process and the final products before full production starts.

Weathering Fastness: All ink sets pass an internal weathering test. However, the testing and guarantee to achieve a certain weathering resistance are the responsibilities of the manufacturer of these products, Durst accepts no liability and provides no guarantee in this respect. We therefore recommend that every print manufacturer thoroughly tests the production process and the final products by means of accelerated ageing tests before full production starts.