Durst FLT LED Ink

This highly flexible ink is compatible with all Durst LED roll-to-roll printers and is suitable for a wide range of materials demanding highest levels of flexibility. This includes self-adhesive substrates, transparent films, PVC and applications such as Day&Night, Color-White-Color and backlit prints on highly flexible substrates (Samba, Pearl,..).

Available Colors

Printer Platform

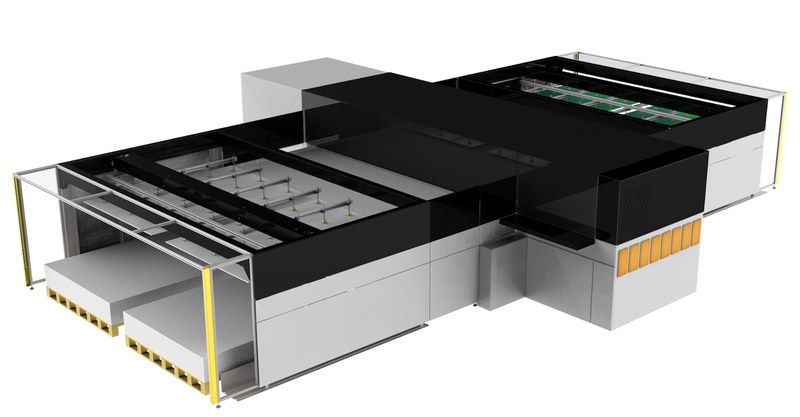

- P5 500

Benefits

- Very good flexibility

- Good adhesion

- Low odor

Substrate Application Example

- Blackback textiles

- Pearl textile

- Banner

- Self-adhesive vinyl

- Clear film

Additional Information

The high flexibility and adhesion level results in a certain tackiness of the ink. Therefore, this ink is not recommended for stacking boards and paper roll applications.

Disclaimer: Any written information, spoken technical advice and correspondence represents the currently available product information to Durst, this also applies to information supplied from tests and samples. All technical information and advices do not constitute a guarantee or warranty for specific product properties or its suitability for specific applications. The testing and guarantee to achieve a certain product performance are the responsibilities of the manufacturer of these products, Durst accepts no liability and provides no guarantee in this respect.

We therefore recommend that every print manufacturer thoroughly tests the production process and the final products before full production starts.

Weathering Fastness: All ink sets pass an internal weathering test. However, the testing and guarantee to achieve a certain weathering resistance are the responsibilities of the manufacturer of these products, Durst accepts no liability and provides no guarantee in this respect. We therefore recommend that every print manufacturer thoroughly tests the production process and the final products by means of accelerated ageing tests before full production starts.