Durst Roll LED Ink

This ink is designed as a LED UV curing version for roll-to-roll presses but can also be used on P5 hybrid presses and represents the most economical solution.

Due to its flexibility and adhesion range this ink is very versatile, plays a particularly important roll for roll-to-roll applications and allows a very wide application range on P5 hybrid printers from flexible media to boards.

Besides standard materials such as PVC, this ink is also particularly suitable for media requiring high ink adhesion such as acrylic, polycarbonate, polystyrene and polypropylene.

Available Colors

Printer Platform

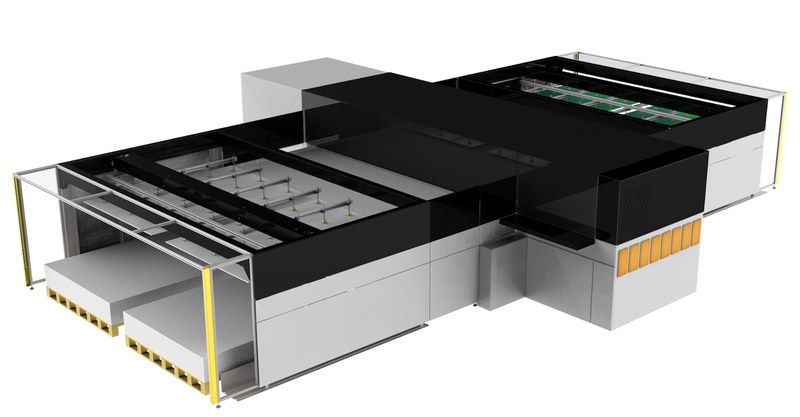

- P5 350 / 210 / HS

- P5 500

Benefits

- Economical solution

- Very good adhesion

- Good flexibility

- Runability

Substrate Application Example

- Blackback textiles

- Banner

- Self-adhesive vinyl

- Fabrics

- Clear film

- Canvas Paper

- Pearl textile

- Pressure Sensitive (Self-adhesive foil)

- Plastic hard foam board (e.g. Forex)

- Soft foam board (e.g. Kapa)

- Folding carton

- Acrylic/polycarbonate

- Polypropylene

- Rigid and flexiblePVC/Styrene

Recommendations

For certain high flexible applications on Durst presses such as Day&Night, Color-White-Color on highly flexible substrates (Pearl, Samba, Mambo,..) including subsequent processing (cross folding), the use of FLT LED W ink is recommended to give best possible results on Durst presses.

Printing in glossy mode may be helpful to increase color gamut and abrasion resistance of the ink if required.

The use of lights inks also beneficially improves scratch resistance on light shade areas.

Additional Information

Tack/Stackability: The flexibility and high adhesion level of this ink results in a certain limitation in terms of stackabilty. Therefore, stackability for corrugated boards, acrylic boards and paper applications may be possible with certain limitations.

Abrasion / Scratch resistance: Due to the flexibility and softness of the formed ink layer combined with the high adhesion level of the ink, abrasion and scratch resistance may present a certain limitation.

Disclaimer: Any written information, spoken technical advice and correspondence represents the currently available product information to Durst, this also applies to information supplied from tests and samples. All technical information and advices do not constitute a guarantee or warranty for specific product properties or its suitability for specific applications. The testing and guarantee to achieve a certain product performance are the responsibilities of the manufacturer of these products, Durst accepts no liability and provides no guarantee in this respect.

We therefore recommend that every print manufacturer thoroughly tests the production process and the final products before full production starts.

Weathering Fastness: All ink sets pass an internal weathering test. However, the testing and guarantee to achieve a certain weathering resistance are the responsibilities of the manufacturer of these products, Durst accepts no liability and provides no guarantee in this respect. We therefore recommend that every print manufacturer thoroughly tests the production process and the final products by means of accelerated ageing tests before full production starts.