GAMMA 141DG

Revolutionary system for digital printing of structures on ceramic tiles

The Gamma 141 DG single pass digital structure printer is designed for handling tile widths up to 1400 mm and allows the creation of an unlimited number of unique designs with impressive visual matching and tactile effects to assure a very evident value added.

Equipped with the proprietary Durst RockJET™ printhead technology, it allows for the first time the digital printing of ceramic glazes with very large particle sizes (>45 microns), similar to traditional glazes for the creation of highly defined, variable structures with significant amounts of glazes applied in a targeted manner. The extreme fidelity in the reproduction of the structures in high definition and in total correspondence with the graphics offers a very natural result, which significantly differentiates them from those made with traditional technologies with very limited and therefore repetitive structures not in register with the design. The visual and tactile effects obtained with Gamma 141 DG make the final product look extremely natural and hardly distinguishable from natural materials. This system finally allows to get out of the current product flattening (appiattimento) through a real technological product innovation that cannot be imitated without having this unique and innovative printing technology in house.

Gamma DG is designed for a full synchronization with the Gamma XD digital décor printer to assure a substantial product differentiation with a clear visible value added which cannot be achieved with any other technology.

- Revolutionary single pass digital structure printing technology

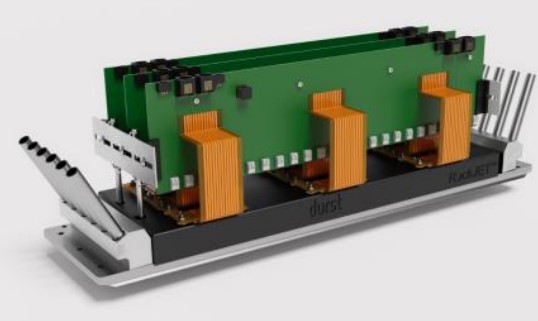

- Proprietary Durst “RockJET™” print head and “VariStructure™” glaze jetting technologies

- Development of innovative, unique products with very natural effects thanks to the digitally created non-repeating structures in perfect match with the décor (design).

- New optical and haptic effects, which emphasize the advantages and naturalness of the ceramic tile even more than other materials. This makes it visually and tactile difficult to distinguish from natural stone, marble, wood products, while having all the superior properties and characteristics of ceramic tiles

- Selective, high resolution glazing & structure printing technology for natural look

- Cost effective large particle size glazes (> 45 microns) with high viscosity

- Glaze laydown up to 1 kg/m2 of glaze at 20m/min.

- Full synchronization with Gamma XD (operational and file/data handling)

- High production flexibility, especially with small batch sizes and frequent product changes, which can be automated and optimized in terms of time and costs.

SUSTAINABLE & COST SAVING TECHNOLOGY

- On-Demand-Production = optimized use of resources

- Water-based glazes for low emissions

- Drastically reduced glaze waste

- Reduced water consumption for cleaning

- No mold inventory

- Minimized downtime / optimized energy utilization

- Economical short runs

- Short total time from design creation to finished product

TECHNOLOGICAL INNOVATION FOR A SUBSTANTIAL DIVERSIFICATION

Durst True Digital Glazing technology for printing ceramic glazes is seen as the next and even more important revolution in the tile sector after digital decoration.

Immediately noticeable added value: high resolution structure printed with Durst Gamma DG ("RockJETTM" and "VariStructure TM" technologies) on a flat tile in total correspondence with the graphics for an extremely realistic, natural look and feel.

Versatility: Printing very fine graphical patterns & natural design patterns with same technology

Thanks to the total correspondence of the high definition and graduated structure with the natural wood décor, the finished “ceramic” wood floor can hardly be distinguished from real wood

TESTPRINT DIFFERENT DIGITAL STRUCTURES ON SAME TILE WITH FLAT MOLD

Digital structure printing with Durst Gamma DG also brings important advantages in the development and industrialization phase of new products. It is now possible to test several different structures on a single tile without both additional costs (production of different mechanical molds) and also retooling.

Testing different structures on the same tile – fast and very cost effective product development, especially important for larger tile sizes and tile slabs

Gamma DG Series feature an open glaze system with glazes available from all major Durst certified glaze manufactures.

The core technology is the proprietary and patented Durst RockJETTM print head specifically developed and manufactured by Durst for digital printing of ceramic glazes with similar characteristics and properties of traditional glazes. The revolutionary innovation is that Durst RockJETTM is the first print head able to jet glazes on flat surfaces with very large particle sizes (>45 microns) and with high viscosities to create important and highly defined structures with significant amounts of glazes applied in a targeted manner. In combination with the Durst VariStructureTM technology for a controlled, variable laydown very smooth transitions for a very realistic and natural look can be obtained.

Durst “RockJETTM” print head

- Gamma PrepStation: central job preparation and print monitoring system

- Industry 4.0 with real-time bidirectional data management

- Synchronization technology between Gamma DG and Gamma XD, complete with barcode printing and reading system

- Gamma Vision System for automatically recognizing the embossed structures on ceramic tiles upstream of Gamma DG to synchronize structures from the press with the structures digitally printed with Gamma DG

Detailed information on request.

Gamma DG Video with interviews (Press Video)

Gamma DG Video with printer in production (Tech Video)

From a technological revolution comes the ceramic hyperrealism