DURST WORKFLOW

Durst Workflow is a browser-based application that handles prepress and production tasks fully automatically. Thanks to preconfigured corrections, data preparation is fast and efficient, and the integrated, powerful Color Engine guarantees outstanding color accuracy right from the start.

Automate your prepress and production tasks from data preparation to printing with Durst Workflow.

COLOR ACCURACY

Durst Workflow was originally developed to guarantee exceptional printing quality and sensational color management for Durst printers. Now available for non-Durst printers, it enables the high expectations of end customers to be met.

BROWSER BASED

Durst Workflow is a browser-based software: you don’t need any additional application to work on it, only a web browser and an internet connection.

PROCESSING SPEED AND COMPLETE PROCESS

Upload, verify, correct and generate print predictable PDF files in a one smooth automatic process. You can integrate these functions with your ERP/MIS solution to bring productivity to an even higher level.

VERSIONING

Every time a change is made to the print item, a new version is created in Durst Workflow, so that the latest version is always being worked on. Every job that has been transferred to the printer is saved with all the settings used and can be produced again removing the chance of making any mistake.

REAL-TIME PRODUCTION DASHBOARD

With Durst Workflow is easy to know which jobs are to be produced.

When a print file is prepared for production, its status is changed accordingly so that the production department knows that the job can be used. The production department can then apply filters according to the due date, so that only the relevant jobs are displayed.

USER MANAGEMENT

The detailed user management allows different departments to have access to the workflow, all of them with specific access to predefined areas to facilitate consistent cooperation avoiding any kind of confusion.

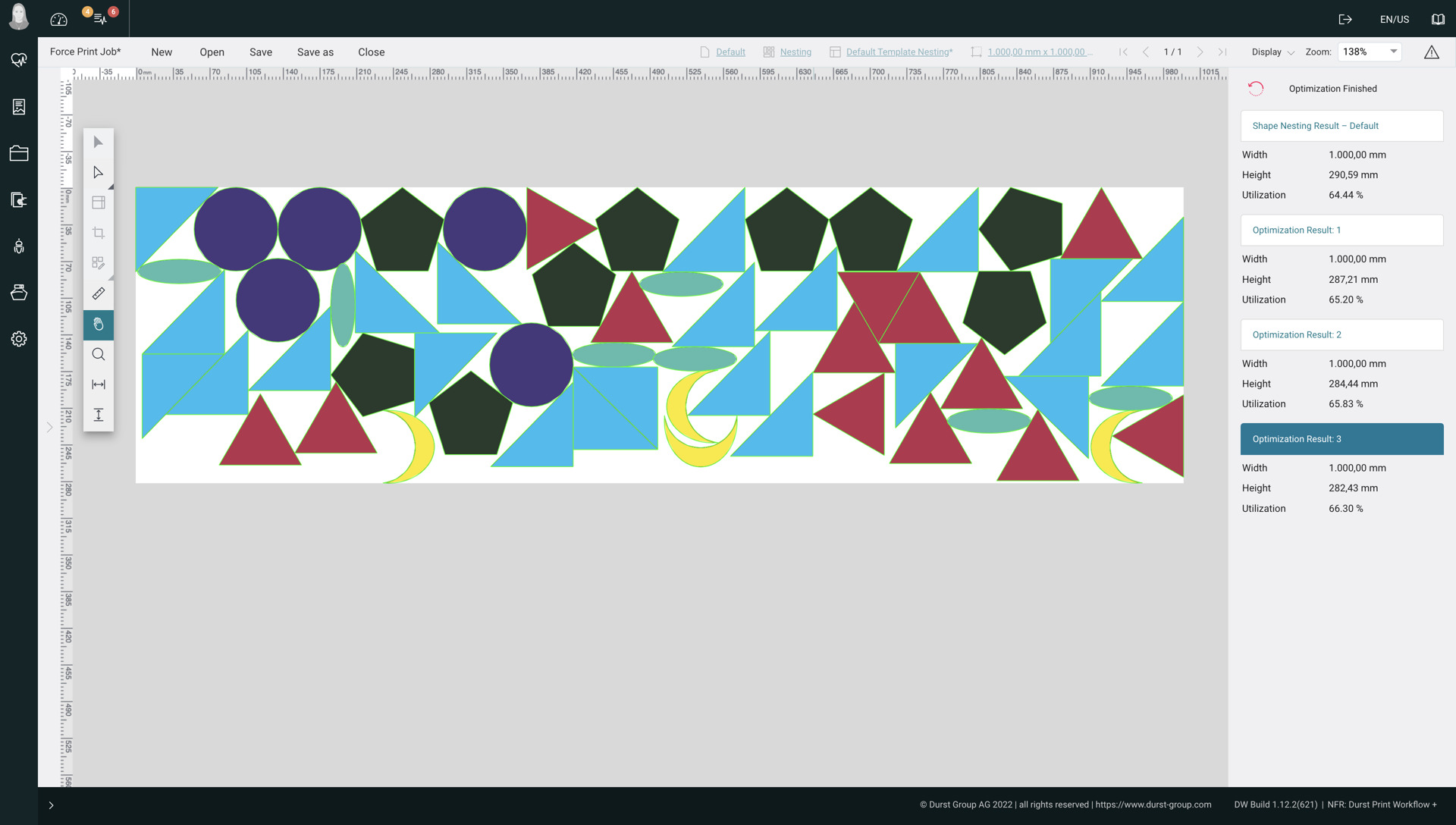

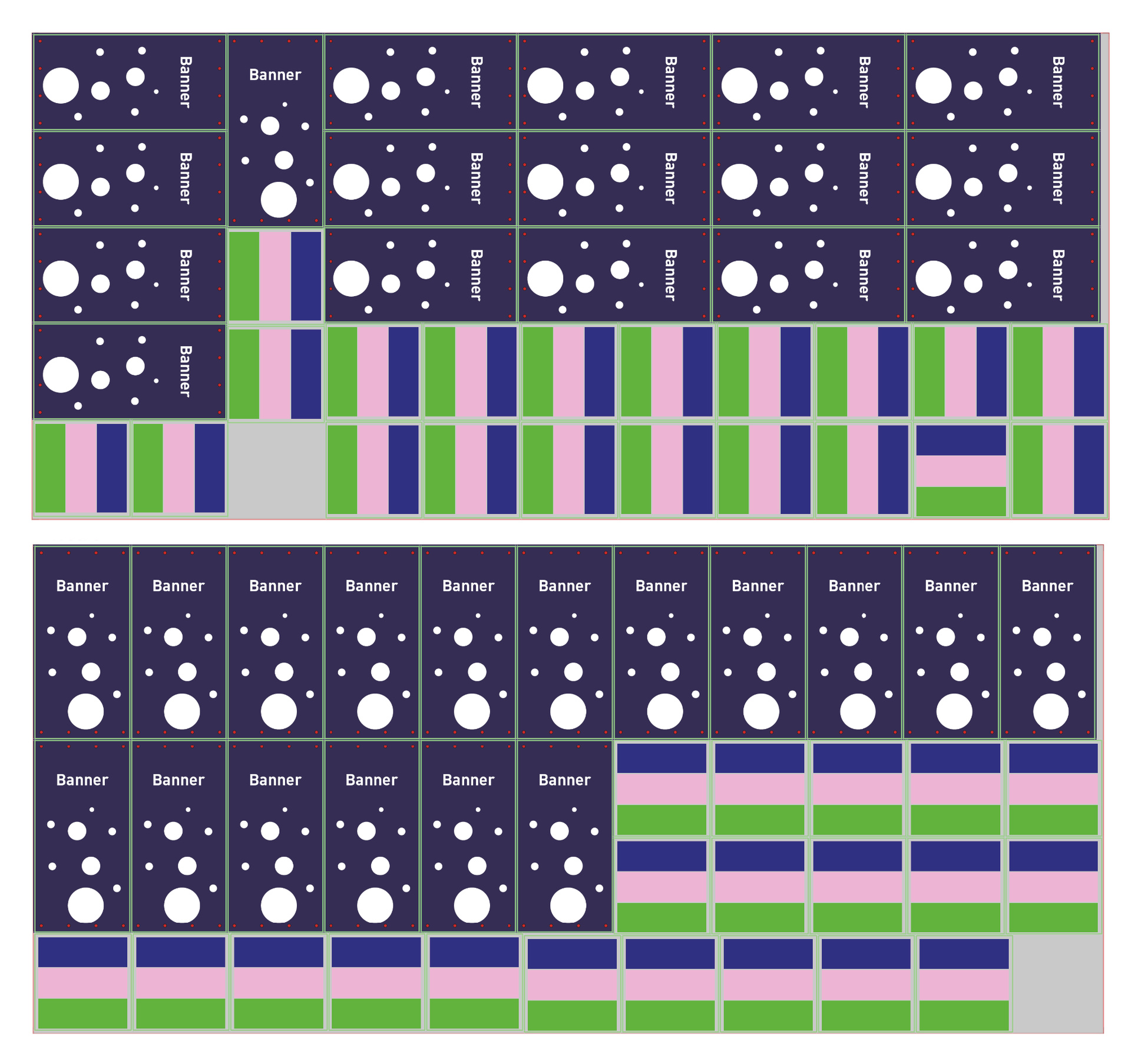

SHAPE NESTING

When you get orders with different shapes, you can impose them in the most efficient way with Durst Workflow. Several settings are at your disposal to generate the best possible outcome. Save them as templates – one step closer to a more automated way for shape nesting.

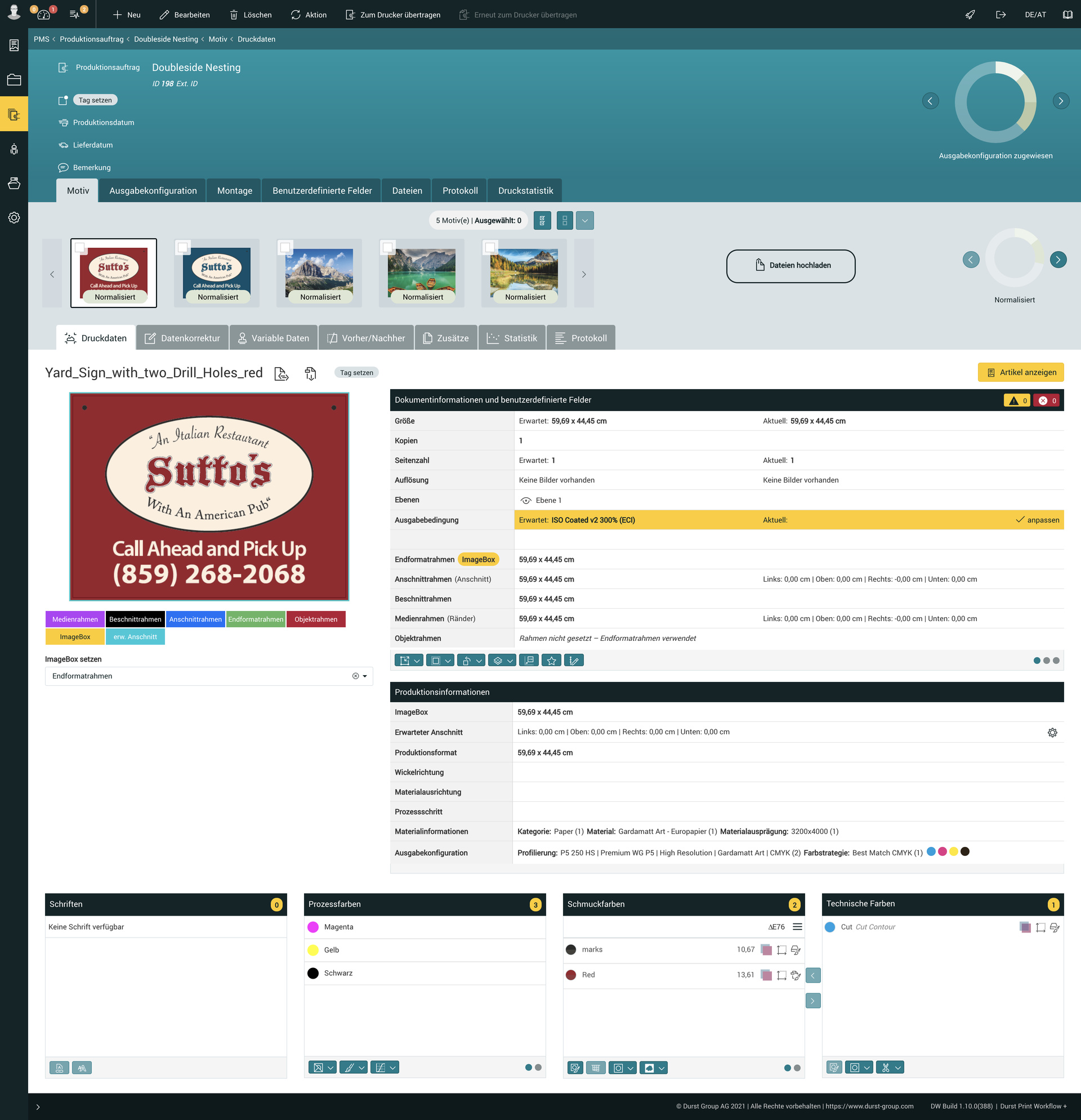

PREFLIGHT

In order to know what a customer file contains, every file that is uploaded into Durst Workflow goes through an automatic preflight check. During this check, all production-relevant information is checked and clearly displayed in the software.

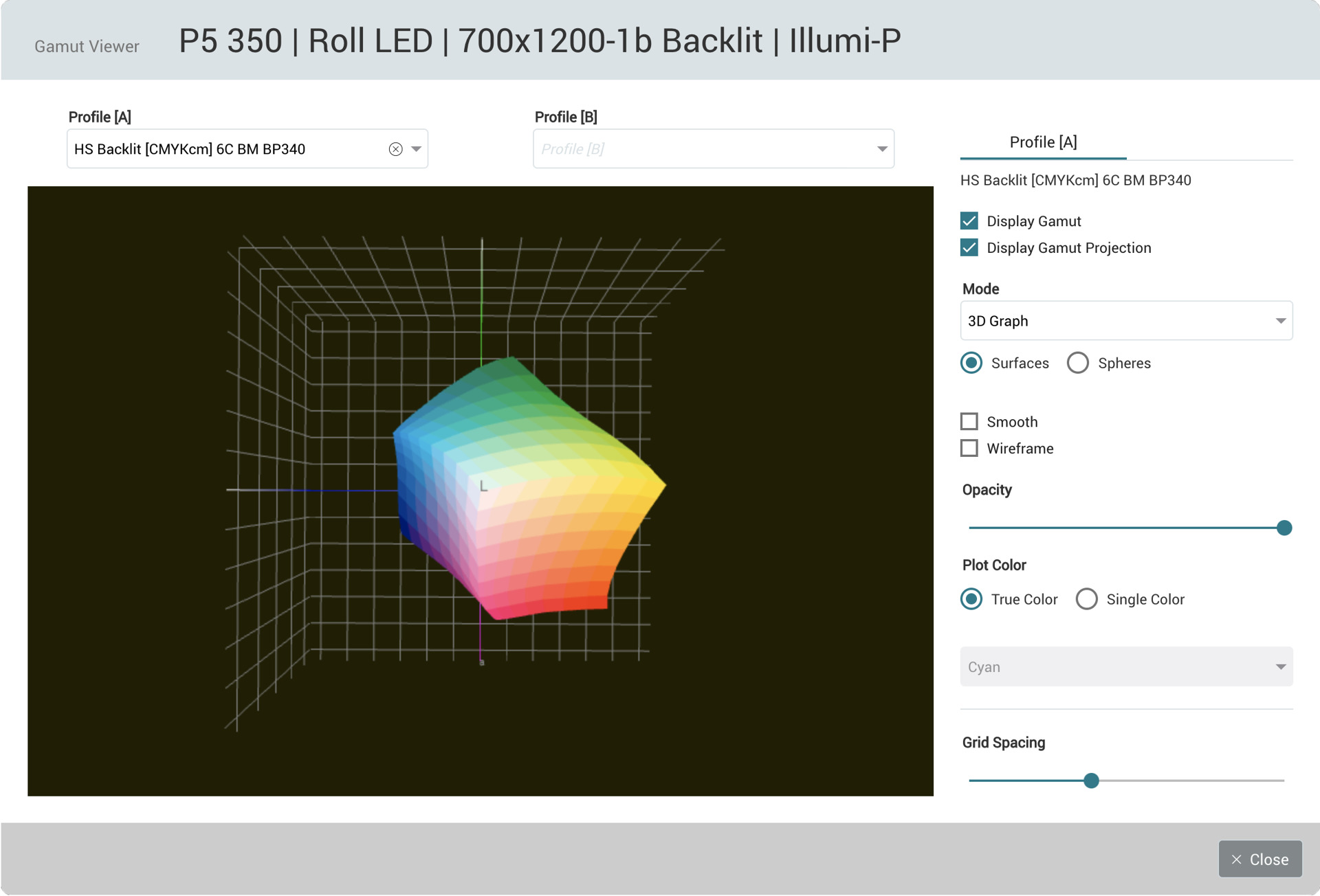

COLOR PROFILE AND GAMUT VIEWER

Substrate profiles are very important for accurate color reproduction. With Durst Workflow you are guided step by step through the creation of a profile.

Advance settings are nonetheless available to allow you to incorporate your color expert knowledge. You can also compare and check your profile with an ISO standard or with another profile thanks to the integrated gamut viewer.

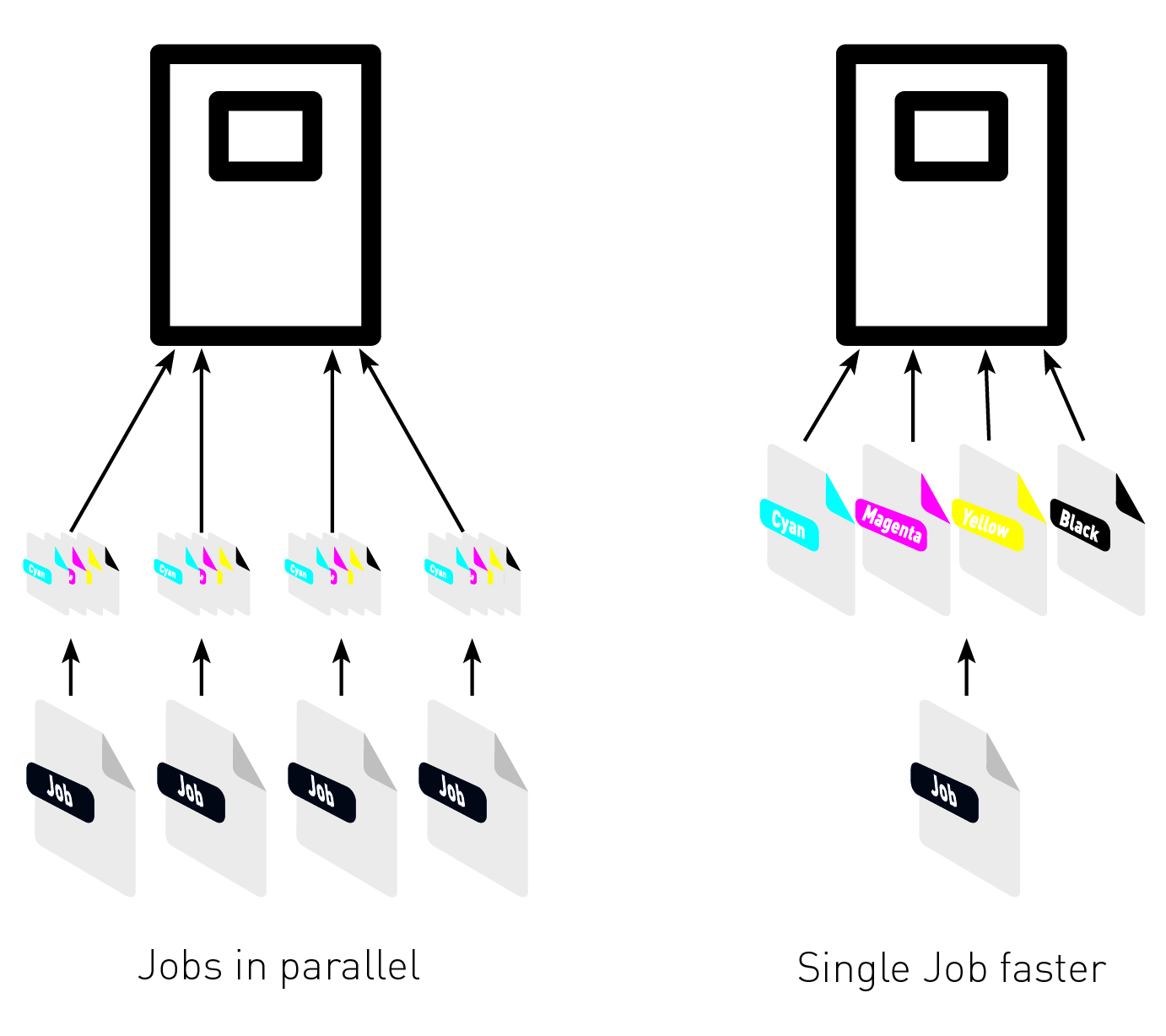

PARALLEL RIPPING

Render print data simultaneously: decide whether up to four jobs should be sent to the printer in parallel or whether a single job should use all available cores to render it even faster.

IMPOSE EDITOR

To enable continuous production, Durst Workflow has an integrated Impose Editor that contains different impose modes such as Step & Repeat, Tiling, different Nesting variants and Manual imposition. Each of the available modes has special setting options, which are finally saved to a template and can be used again and again with just one click.

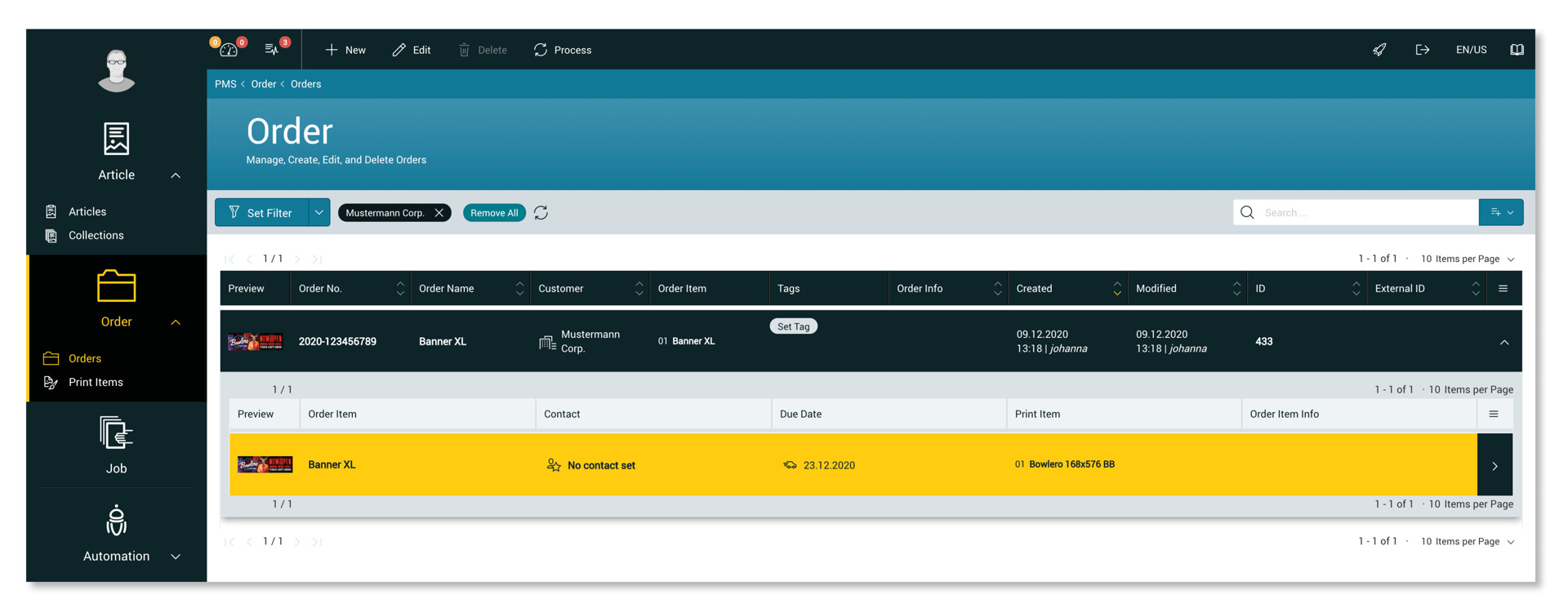

JOB MANAGEMENT

If a print item is loaded into the Workflow, a production job is always created, which contains production-relevant information. If a customer wants a re-production, the file does not have to be uploaded again, no the job with all used parameters is still available in the Workflow and can be produced again with only one click.

SPOT COLOR MANAGEMENT

Along a production often several spot colors are needed, such as technical colors, white, varnish or spot colors from defined spot color libraries. To facilitate the management of these colors, there is the possibility to store spot colors of any kind system wide. Colors saved in the Workflow are automatically recognized and used with the stored settings.

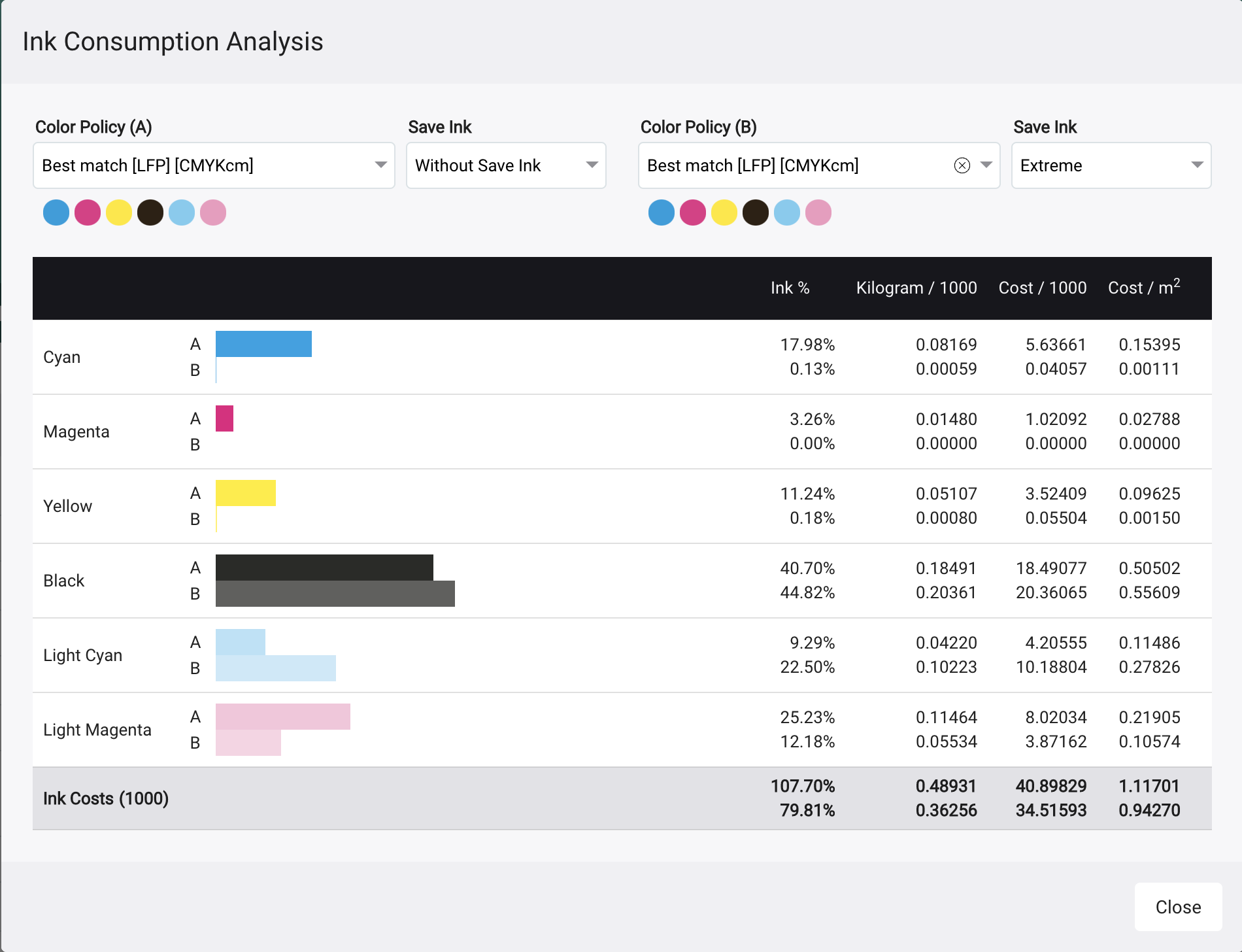

INK SAVING

Durst Workflow makes it possible to save ink with just a few clicks, by simply selecting one of the predefined ink saving profiles. For each of these ink save profiles, an algorithm is applied that reduces the amount of cyan, magenta, and yellow by optimizing the black composition, allowing to save up to 30% on ink consumption.

SUBSTRATE SAVING

If a one-sided or multi-sided nesting is created, you can run an additional algorithm over his assembly to obtain an improved nesting. The built-in algorithm generates a material saving nesting with the previously defined settings.

CORRECTIONS

Durst Workflow makes it possible to automate the prepress work, like adding production information, grommets or bleed. The included data corrections fix around 85% of all typical printing industry errors and all required allowances can be added with just a few clicks. All available corrections can be combined into so-called correction chains and saved with customer-specific values. These correction chains can then be triggered manually or by integration.

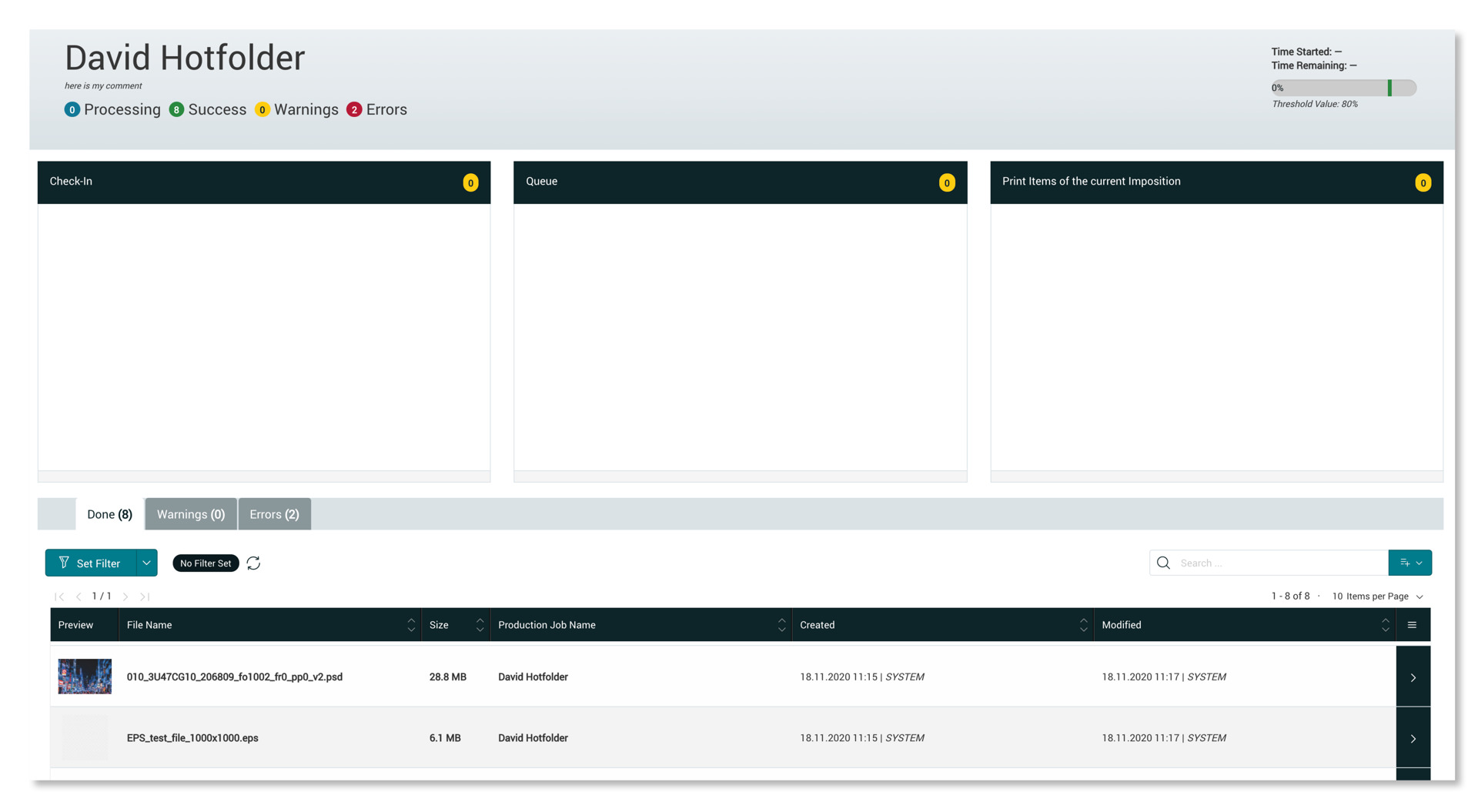

HOTFOLDER

In addition to the classic single-file hot folder, Durst Workflow offers Auto-Nesting, XML and ZIP hot folders, as well as a ZIP for Multitracks hot folder. For each hot folder there are special settings, which are stored when creating the hot folder.

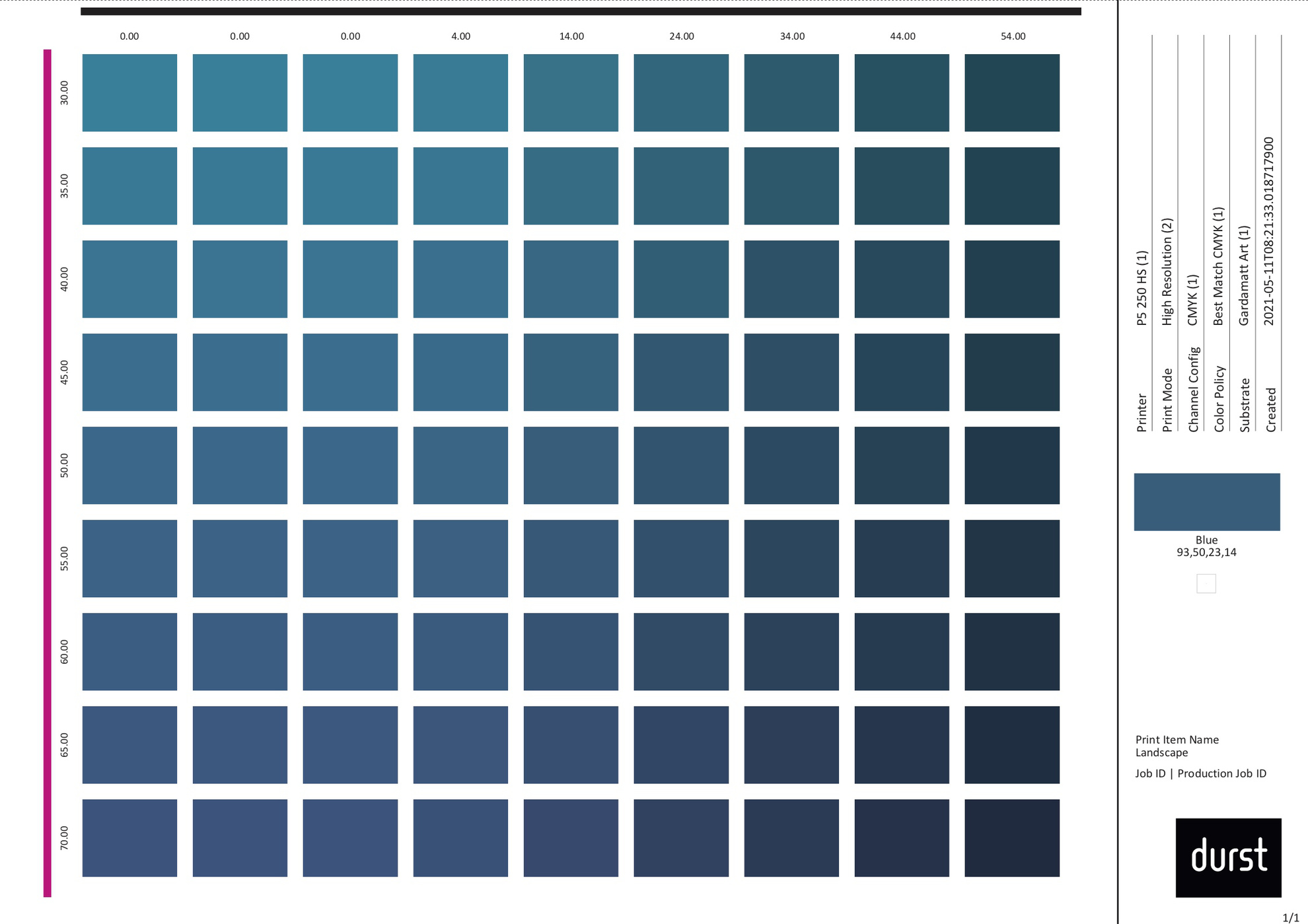

COLOR MATCHING

With the help of grid charts, spot colors with defined deviations can be printed and precisely matched. If your customer has decided on a color definition, this can be stored in the Workflow. This color definition can be saved to the customer or to a special material and will be changed automatically after uploading to the saved color definition.

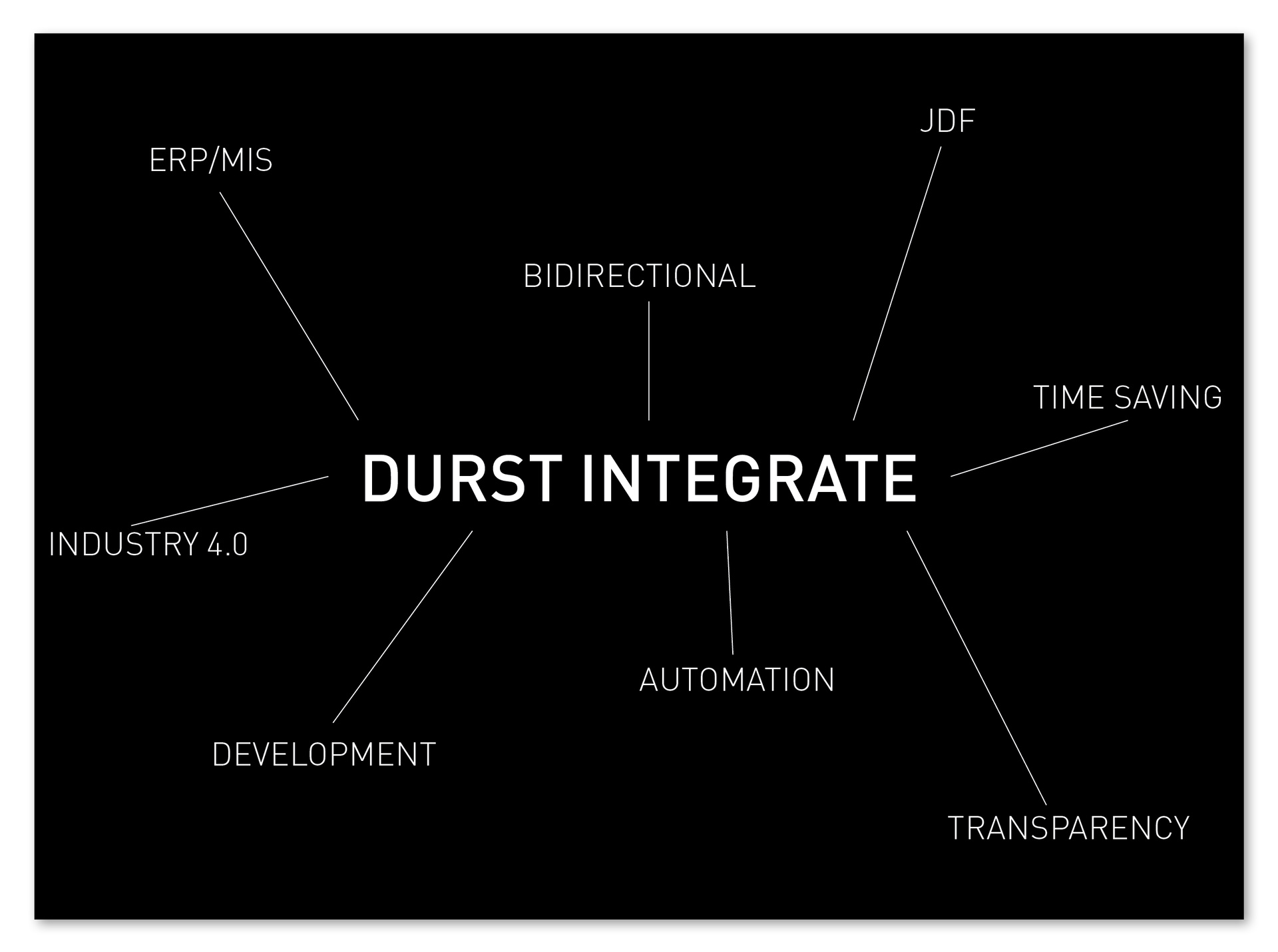

REST API INTEGRATION

In order to be able to control all available functions from the Workflow automatically from the leading system, such as an ERP/MIS system or an eCommerce solution, a Rest API connection is provided.

WORKING WITH PRESS SHEETS

- Barcode /Text Caption

- Motif as big as sheet

- Add marks

WORKING WITH ROLL MATERIAL

- Caption

- Marks

- Settings for nesting or tiling

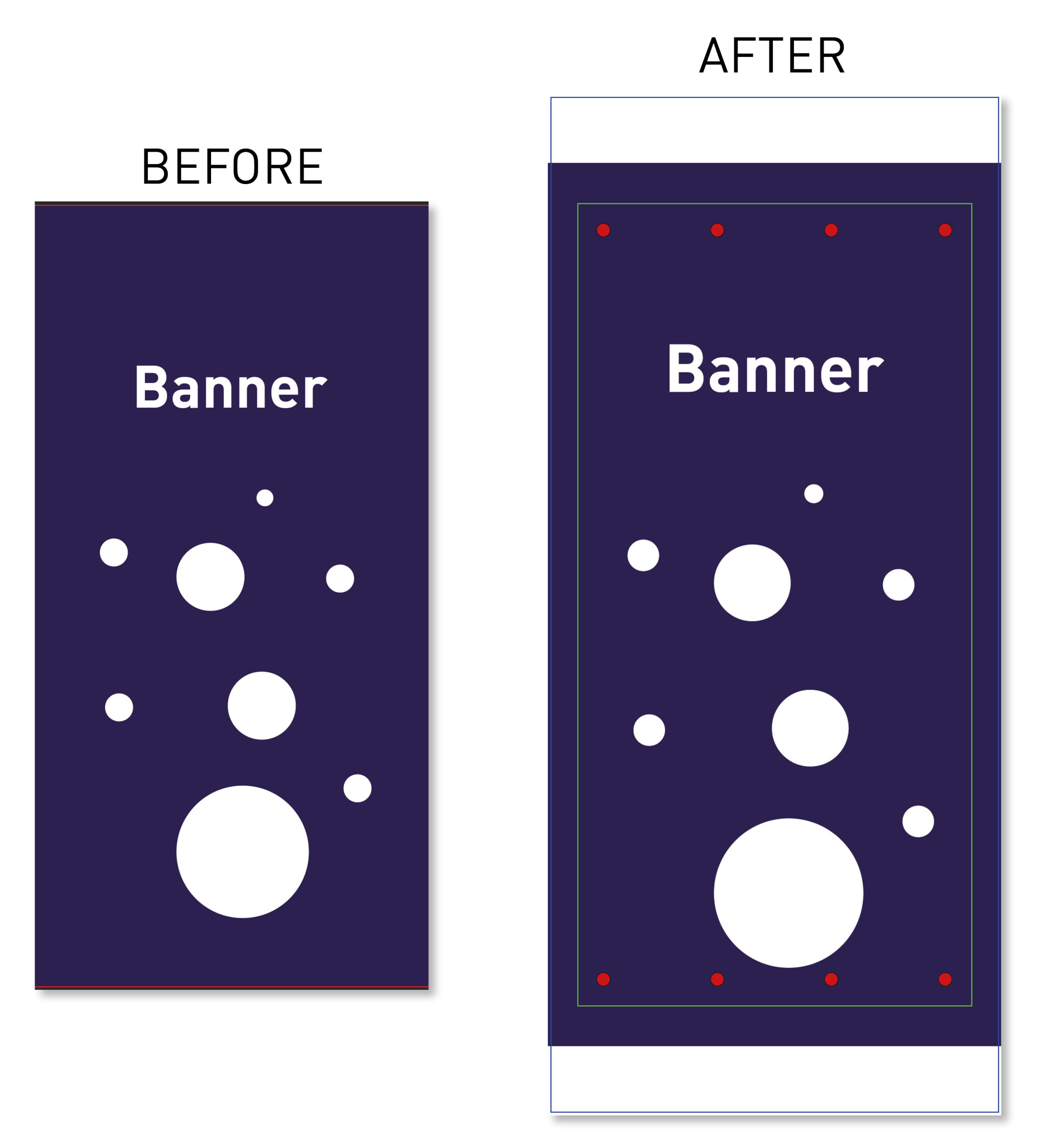

CREATE BANNER

- Create chain

- Apply chain

- Show Before/after

CREATE VDP

- Open in Adobe Illustrator

- Add CSV

- Add QR code & serial number

- Save

- Create Impose & show output